"D:\Inetpub\wwwroot\PROD-ESSN.itcs.hpe.com\us\en\support\titles.xml" is not a valid XML document.

Could not find a part of the path 'D:\Inetpub\wwwroot\PROD-ESSN.itcs.hpe.com\us\en\support\titles.xml'.

HP Quality Policy:

"Providing products, services, and solutions of the highest quality and delivering more value to our customers that earn their respect and loyalty."

Introduction

HP Networking takes great pride in the quality and reliability of its products and believes the quality of its products exceeds other vendors. HP Networking's strong commitment to quality and confidence in its products is evident in offering an industry-leading warranty, including a lifetime duration warranty on most of the product portfolio. HP Networking is committed to a positive customer experience and believes the quality and reliability of our products will provide customers with a strong return on their investment, low cost of ownership, and a satisfied relationship with HP Networking.We measure quality in terms of our customer's experience. We believe we can always do better at understanding our customer's expectations. That belief pushes our standards ever higher improving quality generation to generation, product to product.

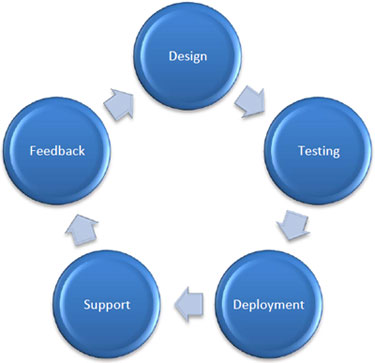

Quality starts with product concept, design and validation within our Research & Development Lab; to product manufacture and deployment with our Supply Chain; to product support and customer feedback. All are essential parts of the HP Quality Improvement Cycle.

When an error in quality happens, we are the best at responding to customer issues. We utilize the HP Quality Improvement Cycle and Lean Six Sigma Quality programs to continually improve and manage our product quality. We apply the necessary corrective actions to ensure it never happens again.

Research & Development

Quality practices within the R&D organization are industry leading and an inherent part of the organizational culture. From product conception, through development, validation and deployment of product, customers can be assured that HP Networking products have quality "designed in" from the earliest phases of the lifecycle.Products progress through the development lifecycle adhering to strict rigors of quality design rules and validation. Facilitating this are dedicated program managers that ensure each product passes very specific quality checks at each product development phase. This methodology ensures the necessary "quality assurance" activities take place throughout the entire product lifecycle.

Included here are comprehensive architectural and design reviews, as well as confirmation of customer use cases, quality requirements and product specifications (performance, features, reliability, safety, etc.).

Proper development starts with detailed specifications and stringent requirements around delivering to those specifications. From partnering with only the highest quality of component suppliers and designing for "x" (manufacturability, reliability, testability, etc.), our team is positioned well to "build-in" quality into our products.

Our products go through a rigorous series of validation steps to ensure specifications are met, and in many cases exceeded. Test plans are reviewed for completeness and hardware and software is stressed to simulate the most extreme environments. From regulatory, to environmental and safety testing and comprehensive "system" testing, customers can rest assured that our validation processes will capture even the most stringent quality standards.

The R&D team works closely with the product Support teams to gather near real-time quality information in order to monitor product quality. Suspected concerns are fed back into the design teams for analysis as part of the HP Quality Improvement Cycle. The "closed-loop" corrective action process results in faster analysis, resolution, and quality improvements.

Supply Chain

The Supply Chain team supports the overall customer experience through excellence in product manufacturing, reliable deliveries and quick response to resolving customer issues.The team ensures components, parts, assemblies and products entering the supply chain meet rigorous standards. All assemblies and products are thoroughly tested and validated each step throughout the manufacturing process. Regular customer centric out of box audits is performed on all products prior to shipment.

We continuously address every stage of our supply chain to improve our products, our delivery systems and our response to customer issues through the HP Quality Improvement Cycle.

Improvement processes include:- Early engagement between Design and Manufacturing teams to ensure new product designs allow for enhanced testing, consistent soldering and assembling techniques, reliable component selections and robust packaging designs. Followed up by validation of results though early monitoring and analysis of field failures to identify immediate corrective actions as well as identifying improvement opportunities for future designs.

- Factory Quality, ISO 9001-2000, ISO 14001, UL/CSA certifications, various regulatory certifications required for shipment into countries worldwide and compliancy with EU and other worldwide country's RoHS regulatory standards. Continuous supplier quality management through monitoring and issue resolution and regular product audits which feed back into the improvement of daily supplier operations.

- Delivery Quality includes distribution site audits, regular inspections for package damage, feeding back into the improvement of packaging design standards.

Global Parts Supply Chain (GPSC)

GPSC assures the quality of its spare parts in the supply chain by maintaining rigorous repair, testing and inspection criteria that equates to that of the manufacturing process. Upon a fault being identified in the supply chain, comprehensive review is conducted to identify the root cause or failure. Corrective action plans and key process indicators are established, maintained and monitored to ensure proper controls.

Continuous Improvement

We continue to improve product quality. At every step - from design and development through production and testing and on into the workplace - we're alert for any opportunity to improve quality and everything we learn goes into making the next generation of HP Networking products all it can be.Our customers are a vital resource. The best information about the quality of the user experience is obtained through customer feedback. We look carefully at customer surveys and service calls, focus groups and field research, sales meetings and so much more - gathering critical feedback that influences our designs, inspires new features, and improves the overall quality of our products and services.

We never stop. We never stop communicating and listening to our customers. We never stop testing our products, raising our standards, designing new features, developing new technologies, and looking for better materials and suppliers. We never stop perfecting our networking products and working to deliver a Total Customer Experience that's second to none, with an industry-leading warranty, a low cost of ownership, and a satisfied relationship with HP Networking.