Replacing a processor

Before you perform this procedure, make sure that you have the following items available:

T-20 Torx screwdriver

Thermal grease (Spare part number: 777298-001)

-

Observe the following alerts.

CAUTION: To avoid damage to the processor or system board, only authorized personnel should attempt to replace or install the processor in this server.CAUTION: If installing a processor with a faster speed, update the system ROM before installing the processor.

To download firmware and view installation instructions, see the Hewlett Packard Enterprise Support Center website.

CAUTION: THE CONTACTS ARE VERY FRAGILE AND EASILY DAMAGED. To avoid damage to the socket or processor, do not touch the contacts. -

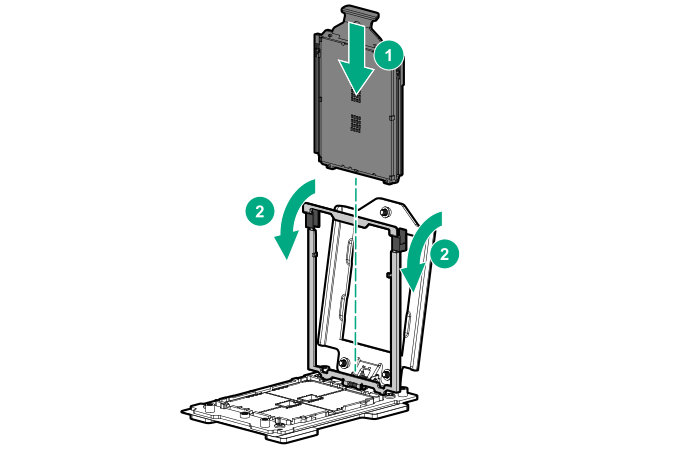

Install the spare processor:

- Hold the processor by its carrier handle and slide the processor into the rail frame until it engages with a click sound.

- Hold the lift tabs near the front end of the rail frame and pivot the rail frame to the closed position.

A click sound indicates that the rail frame is properly engaged.

-

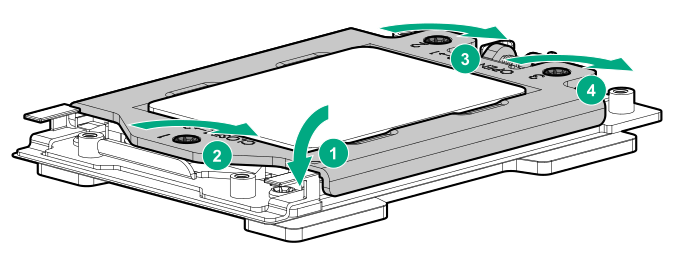

Close the force frame:

CAUTION:

Do not overtighten the screws as this might damage the system board or the processor socket.

- Pivot the spring loaded force frame downward and hold it down (callout 1).

- Use a T-20 Torx screwdriver to tighten the captive screws in the sequence shown in the following image (callouts 2–4).

When using a torque wrench to tighten the screws, apply a torque of 1.58 N-m (14 lbf-in).

-

Apply new thermal grease to the processor in the pattern shown in the following image. Use the full contents of the thermal grease syringe.

-

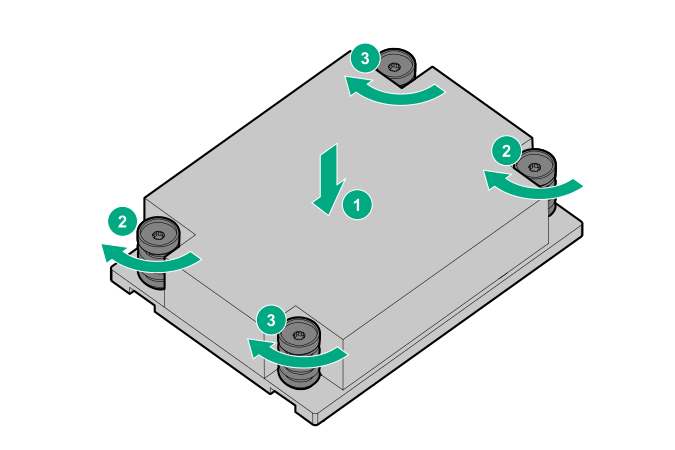

Install the heatsink:

CAUTION:

To prevent mechanical damage or depositing oil on your hands or other contaminant to the heatsink contact surface, hold the heatsink only by the edge of its base plate. Do not touch the heatsink fins.

CAUTION:To prevent thermal failure or component damage, do not move the heatsink once the bottom of its base plate touches the top of the processor. Excessive heatsink movement can cause the thermal grease to smear and become uneven. Voids in the compound can adversely impact the transfer of heat away from the processor.

CAUTION:Heatsink screws must be tightened and loosened in alternating sequence. Do not overtighten the screws as this might damage the system board or the processor socket.

- Position the heatsink on top of the processor, ensuring that it is properly seated before securing the screws.

- Use a T-20 Torx screwdriver to tighten the captive screws in the sequence specified on the heatsink label.

When using a torque wrench to tighten the screws, apply a torque of 1.58 N-m (14 lbf-in).

- If removed, install the air baffle.

- Install the access panel.

- Install the server into the rack.

- Power up the server.

- If removed, install the front bezel.